Questions?

Contact product manager,

Paul Desmarais

(508) 399-5771

paul@hydroquipinc.com

Download Literature

Products • Solids Removal

Inclined Plate Clarifiers

Flow rates up to 300 GPM, based on .25 GPM per sq.ft. of projected plate surface area*

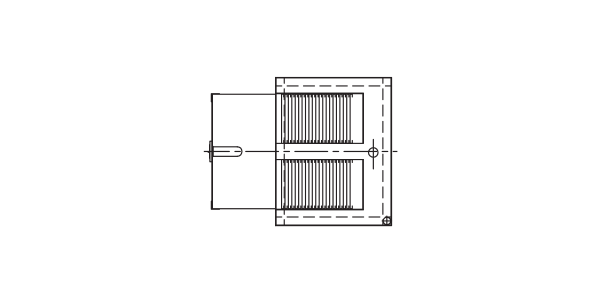

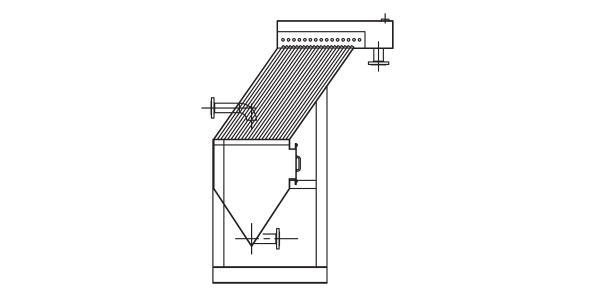

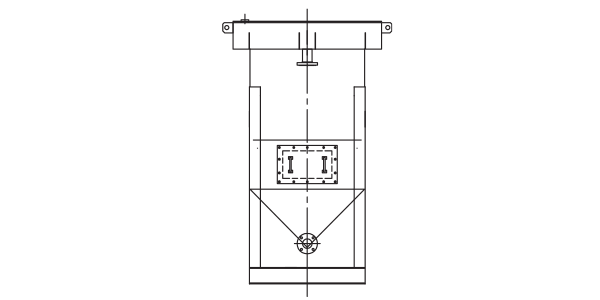

Hydro Quip’s Inclined Plate Clarifiers are designed and manufactured to provide for the precipitation and separation of suspended solids. Our design employs the use of a series of plates inclined at an angle of 45° or 55°. This specialized design allows the unit to perform all of the functions of a conventional solids contact clarifier at a fraction of the space and cost.

All our products are customizable. Size, dimensions, material of construction, plate spacing and angle of repose can be altered to suit your application.

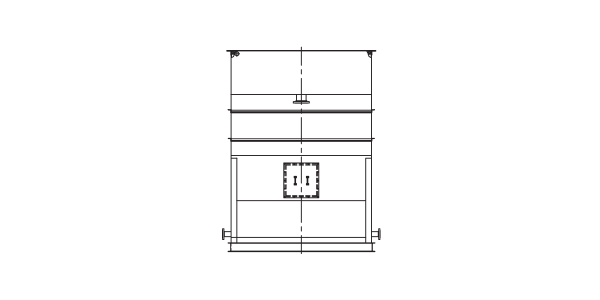

To treat chemical and mechanical emulsions or dissolved solids, a Mix and Flocc Tank is available as an option. The chemicals in the tank will precipitate the emulsions and dissolved solids, while the mixers keep them in suspension before entering the clarifier. This process makes removal more efficient.

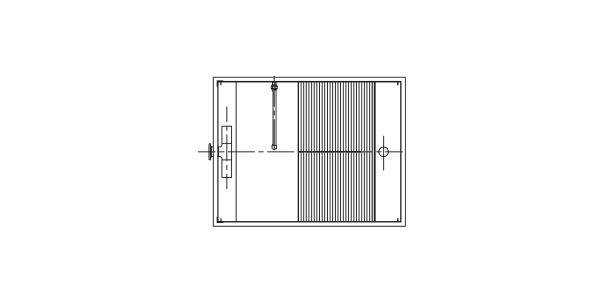

LP Model

An inclined plate clarifier for the separation of suspended solids from water.

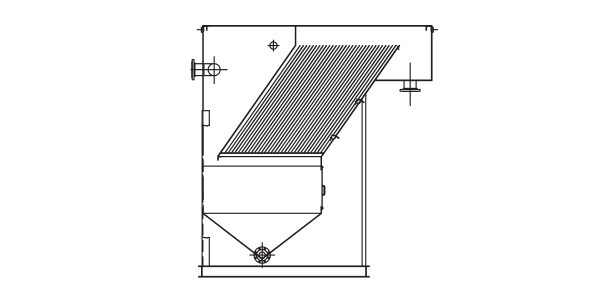

LP-Q Model

An inclined plate clarifier with a quiescent zone for the separation of suspended solids and trace amounts of oil in water.

Equipment Options

- Mix and Flocc Tank

- Ladder/Stairs and Platform

- Mixers

- Covers

- Chemical Dosing Pumps

- Chemical Feed Equipment

- Sludge Pump/ Augers

- Control Panels/ Instrumentation

- Sampling Ports

- Thickening Compartment

- Intermittent clean water backflush

- Activated Sludge Recycling

Applications

- Process Water from hazardous waste site remediation; chemicals, plastics and rubber industry; utlity/energy; academic, medical, and research facilities

- Produced Water for the oil and gas industry

- Wastewater from oil refineries

- Metals Removal from hazardous waste site remediation

- Grinding and Milling Machinery

- Pre-Treatment before evaporators or filtration for OEMs