Products

Emulsion Separators

Typically separating oil from water under normal conditions is not difficult. What can complicate the process is the presence of chemical emulsions, mechanical emulsions and soluble oil (also know as a micro-emulsion). A standard above ground or below ground oil water separator will NOT separate an emulsion, even if you increase the size of the unit. They need to either rise to the top, sink to the bottom or be broken up chemically.

Hydro Quip provides three different emulsion separators. All of these options will also reduce TSS, COD, BOD and FOG concentrations.

Questions?

Contact product manager,

Paul Desmarais

(508) 399-5771

paul@hydroquipinc.com

Dissolved Air Floatation (DAF) System

Dissolved Air Flotation (DAF) is a mechanical process using ultra fine air bubbles to separate somewhat neutral or positively buoyant contaminants from water. These contaminants form nuclei on which microscopic air bubbles coalesce. The air bubbles add buoyancy to the contaminants, causing them to float to the surface.

Emulsification Breaking Separator

This all-in-one unit treats a chemical emulsion by lowering the pH, coalescing, and then neutralizing the wastewater before discharge. By destabilizing the emulsion, the oil will separate by gravity. Both mechanical and chemical emulsions can be destabilized by chemical treatment and coalescing.

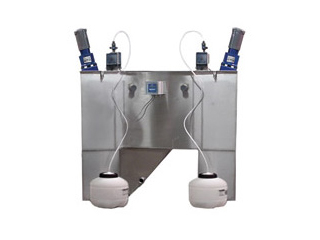

Inclined Plate Clarifier with Mix & Flocc Tank

The continuous flow Inclined Plate Clarifier with Mix & Flocc Tank separates mechanical and chemical emulsions and colloidal contaminants from wastewater as a single flow-through operation. The use of polymers or other chemical additives will help precipitate the contaminants to the hopper compartment for removal.